Finding the Right Partner: A Guide to Selecting the Best Multi Ply Labels Manufacturer

In the ever-evolving packaging industry, the demand for

Multi Ply Labels has grown significantly,

with the global market projected to reach approximately

$30 billion by 2025, according to a recent report

by MarketsandMarkets.

These labels are not only essential for product identification but also play a crucial role in

enhancing brand visibility

and compliance with regulatory requirements. As businesses seek to optimize their packaging solutions,

partnering with a world-class manufacturer becomes imperative.

Selecting the right Multi Ply Labels manufacturer

can directly impact

product quality and

operational efficiency. In this guide,

we will explore the essential factors to consider when choosing a manufacturer, ensuring you leverage

top-notch expertise from leading factories in China that excel in delivering outstanding manufacturing capabilities.

Understanding Multi Ply Labels: Importance and Applications

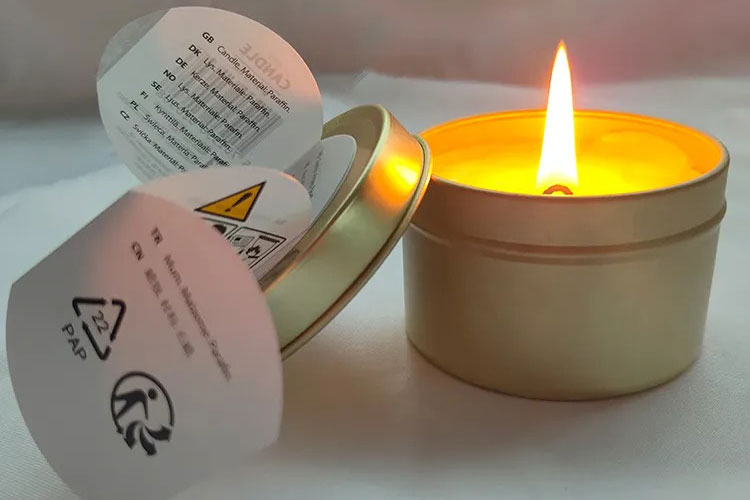

Multi Ply Labels have become increasingly important across various industries due to their unique functionality and versatility. These labels consist of several layers, allowing for additional information to be included without occupying extra space. This is particularly valuable in sectors such as pharmaceuticals, where detailed instructions and compliance information are crucial. Furthermore, in food and beverage applications, multi ply labels can provide essential information on ingredients, nutritional facts, and promotional offers, enhancing consumer engagement while meeting regulatory standards.

The applications of multi ply labels extend beyond basic identification purposes. For instance, advancements in technology have led to methods such as multi-label classification in data analysis, where various relevant labels can be assigned to a single dataset. This is particularly applicable in fields like medical diagnostics and equipment monitoring, where multiple factors need to be labeled and assessed simultaneously. By integrating such intelligent labeling techniques, manufacturers can improve product traceability and adherence to safety standards, ultimately benefiting not only the business but also the end consumer. As industries continue to innovate, the importance of selecting the right multi ply labels manufacturer becomes clear, allowing businesses to leverage the full potential of these advanced labeling solutions.

Multi Ply Labels: Key Features and Applications

Key Qualities to Look for in a Multi Ply Labels Manufacturer

When searching for the ideal multi ply labels manufacturer, it's essential to identify key qualities that can significantly impact your product's success. One crucial factor is the manufacturer's experience in the industry. A seasoned company is likely to have a better understanding of the requirements, technologies, and challenges involved in producing high-quality multi ply labels. Look for a manufacturer with a proven track record and substantial portfolio of successful projects, which can indicate their reliability and commitment to quality.

Another important quality to consider is the versatility of the manufacturer. A good multi ply labels manufacturer should be able to offer a range of materials, adhesives, and printing technologies to cater to diverse applications. This flexibility allows you to choose options that best suit your product needs and branding requirements. Additionally, exceptional customer service is vital; a manufacturer that values communication and support can help you navigate through the production process more smoothly, ensuring that your project runs efficiently and meets deadlines.

Evaluating Manufacturing Capabilities and Technology in China

When selecting a multi-ply labels manufacturer in China, evaluating their manufacturing capabilities and technology is crucial. The ability to produce high-quality labels consistently hinges on the machinery and techniques used in the manufacturing process.

Advanced technology, such as digital printing and efficient die-cutting methods, can significantly enhance operational efficiency and reduce production times. Consequently, it is vital to seek out manufacturers who invest in modern equipment and stay updated with industry innovations.

Advanced technology, such as digital printing and efficient die-cutting methods, can significantly enhance operational efficiency and reduce production times. Consequently, it is vital to seek out manufacturers who invest in modern equipment and stay updated with industry innovations.

Additionally, consider the manufacturer's expertise in handling various materials and customizations. A reliable partner should demonstrate proficiency in producing labels that meet diverse industry standards while offering flexibility in design and functionality.

It’s beneficial to review their portfolio and obtain samples to evaluate the quality of their products firsthand. Engaging with manufacturers who prioritize research and development can also ensure that they are proactive in adopting sustainable practices, which are increasingly important in today’s market landscape. By focusing on these key aspects, you can identify a partner that aligns with your quality and sustainability goals.

Assessing Export Experience and Global Reach in Multi Ply Labels

When selecting a multi ply labels manufacturer, assessing export experience and global reach is crucial. Manufacturers with a strong export track record demonstrate reliability and an understanding of diverse market needs. According to a report by Smithers Pira, the global labels market is expected to reach $45.1 billion by 2025, underlining the importance of partnering with a manufacturer that can meet increasing demands internationally. A manufacturer’s ability to navigate varying regulations and customs requirements in different countries ensures smoother transactions and enhances your brand's visibility across global markets.

**Tip:** When evaluating potential manufacturers, inquire about their previous export projects. Look for those with experience in the regions where you plan to sell your products. This insight can provide reassurance about their capability to handle international logistics effectively.

Additionally, consider the manufacturer’s strategic partnerships and distribution networks. Strong global connections often translate to better pricing and availability of raw materials, resulting in more competitive products. Data from Grand View Research indicates that companies with expansive global networks often experience 20% to 30% faster order fulfillment rates than their counterparts.

**Tip:** Request references or case studies from the manufacturers to gauge their success in previous export scenarios. This can give you confidence in their ability to meet your operational and logistical needs.

Finding the Right Partner: A Guide to Selecting the Best Multi Ply Labels Manufacturer - Assessing Export Experience and Global Reach in Multi Ply Labels

| Manufacturer Location |

Years of Export Experience |

Global Reach (Continents Served) |

Product Specialization |

Annual Export Volume (Units) |

| North America |

15 |

3 |

Custom Multi Ply Labels |

500,000 |

| Europe |

10 |

4 |

Eco-friendly Multi Ply Labels |

300,000 |

| Asia |

20 |

5 |

Industrial Multi Ply Labels |

1,000,000 |

| South America |

8 |

2 |

Food Safety Labels |

200,000 |

| Africa |

5 |

1 |

Pharmaceutical Multi Ply Labels |

100,000 |

Building a Sustainable Partnership with Your Labels Manufacturer

Building a sustainable partnership with your labels manufacturer is essential for long-term success in any business. When selecting a multi-ply labels manufacturer, it’s important to prioritize not only the quality of their products but also their commitment to sustainability. This involves looking for manufacturers who implement eco-friendly practices in their production processes, such as using recyclable materials and reducing waste. By collaborating with a manufacturer that shares your values regarding environmental responsibility, you can enhance your brand’s reputation and contribute positively to the planet.

Effective communication also plays a crucial role in fostering a sustainable partnership. Establishing clear expectations from the outset can help avoid misunderstandings and promote a collaborative atmosphere. Regular check-ins and feedback sessions are vital for maintaining alignment on quality and production timelines. Furthermore, a manufacturer that is open to innovation and adapts to market changes will be more likely to grow alongside your business. By nurturing this relationship, you can create a dynamic partnership that not only meets your immediate labeling needs but also evolves to address future challenges and opportunities in the marketplace.

Advanced technology, such as digital printing and efficient die-cutting methods, can significantly enhance operational efficiency and reduce production times. Consequently, it is vital to seek out manufacturers who invest in modern equipment and stay updated with industry innovations.

Advanced technology, such as digital printing and efficient die-cutting methods, can significantly enhance operational efficiency and reduce production times. Consequently, it is vital to seek out manufacturers who invest in modern equipment and stay updated with industry innovations.