Choosing the right delivery boxes for your shipping needs can significantly impact both your business's efficiency and customer satisfaction. According to John Smith, an expert in packaging solutions, "The right delivery boxes not only ensure products arrive in perfect condition but also enhance your brand image." With the ever-growing demand for reliable shipping methods, understanding the various types of delivery boxes available on the market is crucial for businesses of all sizes.

In today's fast-paced e-commerce landscape, selecting the appropriate delivery boxes involves considering a variety of factors including size, material, and durability. The right box can protect your products from damage during transit and resonate with your brand's values. As the logistics industry evolves, it is essential to stay informed about new packaging innovations and eco-friendly options that align with your business goals.

Ultimately, taking the time to evaluate your shipping needs and understanding the characteristics of different delivery boxes can lead to more effective logistics strategies and improved customer experiences. In this guide, we'll explore key considerations and expert tips to help you make informed decisions about the best delivery boxes for your unique shipping requirements.

When choosing delivery boxes for your shipping needs, several key factors require careful consideration. First and foremost, the size and weight of the items being shipped play a crucial role. It’s essential to select boxes that not only fit the products snugly but also provide adequate protection during transit. Overly large boxes can lead to shifting and damage, while boxes that are too small may not accommodate the items securely. Additionally, consider the weight capacity of the boxes to ensure they can withstand the load without risk of breaking or collapsing.

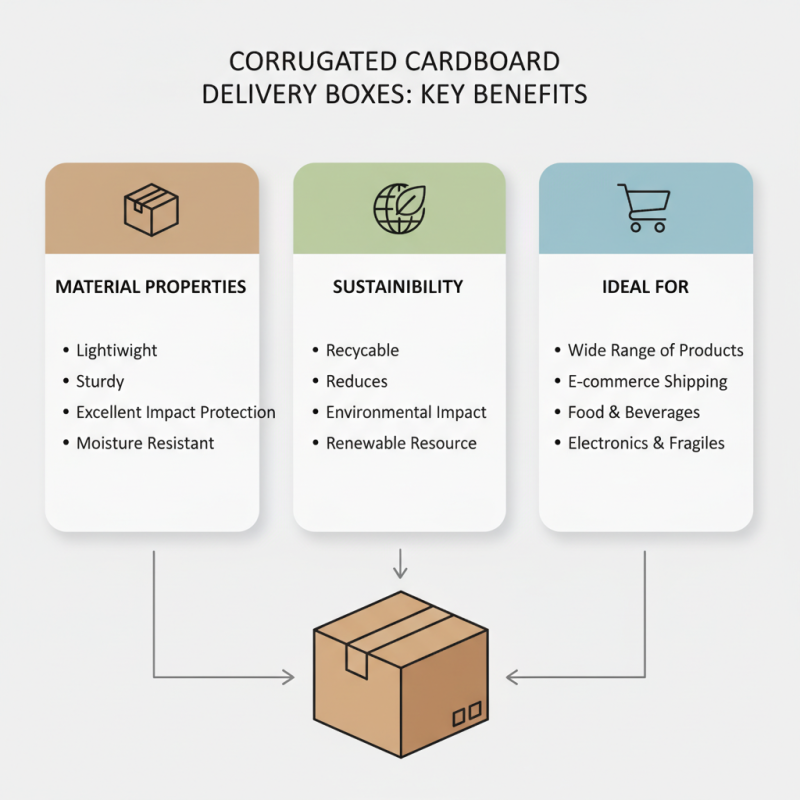

Another important factor is the material of the delivery boxes. Different shipping materials offer varying levels of durability and protection. For instance, corrugated cardboard is lightweight yet strong, making it a popular choice for most shipping needs. However, if your items are fragile or require extra protection from moisture or elements, opting for boxes made of plastic or those that include protective cushioning might be more appropriate. Finally, think about the environmental impact; choosing eco-friendly materials can enhance your brand image while contributing to sustainability efforts.

When selecting delivery boxes for shipping, it's essential to understand the various types available to ensure the right fit for your needs. Among the most common types are corrugated boxes, which are known for their strength and versatility. These boxes consist of a fluted paper layer sandwiched between two flat liners, providing excellent protection for fragile items during transit. They are available in various sizes and can be customized with additional padding or inserts to secure individual products effectively.

Another type of delivery box is the rigid box, which is made from thicker paperboard and offers a premium feel. They are ideal for shipping high-end products and are often used in retail packaging to enhance the unboxing experience for customers. Rigid boxes typically do not collapse and provide a sense of sturdiness, making them suitable for items that require additional protection and a professional presentation.

Mailers, such as padded or envelope mailers, are also popular for shipping smaller, less fragile items. These boxes often come with built-in cushioning and are lightweight, reducing shipping costs while still providing adequate protection. Choosing the appropriate style of delivery box based on the nature of the items being shipped can not only enhance the safety of the products but also improve customer satisfaction upon receipt.

When it comes to shipping products, choosing the right delivery box size is crucial for maximizing efficiency. The first step in sizing delivery boxes is to assess the dimensions of the items that need to be shipped. Take accurate measurements of your products, including their length, width, and height. This will help you determine not only the appropriate box size but also how to arrange multiple items in a single shipment, which can save on shipping costs and improve overall efficiency.

Additionally, consider the weight of the items being shipped. Heavier items may require more robust boxes, while lighter items can be sent in thinner packaging. It’s important to balance the box size with the protection needed during transit; boxes that are too large may result in items shifting around and getting damaged, while overly snug boxes can lead to potential breakage. Utilizing packing materials effectively, such as bubble wrap or packing peanuts, can also enhance protection while allowing for optimal sizing. By carefully calculating both dimensions and weight, you can ensure that your delivery boxes truly meet your shipping needs.

| Box Type | Dimensions (L x W x H) | Weight Limit | Best Use Case |

|---|---|---|---|

| Small Box | 12" x 9" x 6" | 10 lbs | Clothing, Small Electronics |

| Medium Box | 16" x 12" x 8" | 20 lbs | Books, Kitchen Items |

| Large Box | 24" x 18" x 12" | 30 lbs | Toys, Home Appliances |

| Extra Large Box | 36" x 24" x 18" | 50 lbs | Bedding, Sports Equipment |

When selecting delivery boxes, the material used plays a crucial role in determining their effectiveness and suitability for various shipping needs. One of the most common materials is corrugated cardboard, known for its lightweight yet sturdy nature. This type of box provides excellent protection against impacts and moisture, making it ideal for a wide range of products. Additionally, corrugated cardboard is recyclable, which aligns with sustainable packaging practices, reducing environmental impact.

Another popular option is plastic-based materials, such as polyethylene or polypropene. These delivery boxes offer superior durability and resistance to water and chemicals, making them perfect for shipping items that require additional protection. Plastic boxes are also reusable, which can be a cost-effective choice for businesses looking to decrease waste and enhance their brand image through eco-friendly practices. However, it’s essential to consider the nature of the products being shipped alongside the environment in which they will be transported, to choose the most suitable material for optimal protection and efficiency.

When selecting delivery boxes for shipping, understanding cost considerations is crucial for optimizing your budget while ensuring the safe transport of goods. The price of boxes can vary significantly based on materials, size, and functionality. For instance, corrugated cardboard boxes are often favored due to their balance of durability and affordability. However, investing in specialized packaging, such as insulated or custom-sized boxes, may be necessary for fragile or temperature-sensitive items, potentially raising overall costs.

Additionally, it's vital to take into account bulk purchasing options. Buying shipping boxes in larger quantities can lead to substantial savings per unit, making it a financially wise decision for businesses with consistent shipping needs. Furthermore, consider the shipping weight. Heavier boxes may lead to increased shipping fees, so selecting lightweight materials without compromising strength can lead to overall cost reductions. Thoughtful planning and analysis of these factors can help strike a balance between cost-efficiency and product protection, ultimately enhancing your shipping strategy.

Get Free Estimate!