When it comes to shipping goods, selecting the right corrugated box is crucial to ensure that products arrive safely and in optimal condition. According to the Fiber Box Association, the corrugated box industry is witnessing significant growth, with projections estimating a market size expansion to over $100 billion by 2026. This increasing demand emphasizes the importance of mastering the intricacies of choosing an appropriate packaging solution that not only meets customer needs but also aligns with sustainability goals.

As emphasized by industry expert Dr. Emily Hartman, "The right corrugated box can significantly reduce shipping costs while ensuring the protection of your products." This statement underscores the need for businesses to be informed about various factors, including box composition, fluting types, and suitable sizes. Understanding these elements not only contributes to cost-effectiveness but also plays a vital role in minimizing waste in the supply chain, addressing both economic and environmental challenges.

In an era where environmental sustainability is more critical than ever, the corrugated box market continues to evolve. Companies must prioritize the selection process to not only enhance the efficiency of their shipping operations but also align with best practices that support a greener planet.

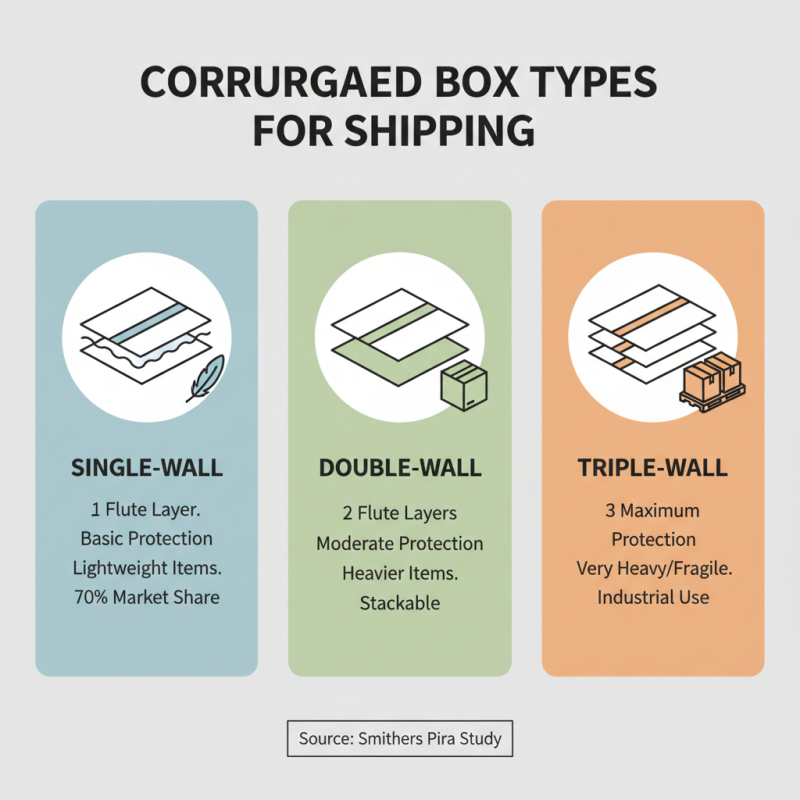

When selecting the best corrugated box for shipping, it is crucial to understand the various types available and their specific applications. Corrugated boxes are primarily classified into three categories: single-wall, double-wall, and triple-wall boxes. Single-wall boxes, consisting of one layer of fluted paper sandwiched between two liners, are ideal for lightweight items that require basic protection. According to a study by Smithers Pira, single-wall boxes account for approximately 70% of the market, highlighting their popularity for general shipping needs.

In contrast, double-wall and triple-wall boxes provide increased strength and durability, making them suitable for heavier items or products that require extra protection during transit. Reports indicate that the demand for double-wall boxes has risen due to their effectiveness in preventing damage from stacking and handling, with their market projected to grow by 5% annually. On the other hand, triple-wall boxes, while more expensive, are used for fragile goods, offering a protective solution that withstands significant impact. Understanding these distinctions is essential for businesses aiming to optimize their shipping processes and ensure the safe delivery of their products.

When selecting a corrugated box for your shipping needs, understanding the factors influencing its strength and durability is critical. One of the primary aspects to consider is the flute type used in the box’s construction. Different flute profiles—such as A, B, C, E, and F—provide varying levels of cushioning and stacking strength. For heavier items, opting for a box with a broader flute can offer better support and resistance against crushing during transport, ensuring that the contents remain protected.

In addition to flute configuration, the material quality also plays a significant role in determining a box's durability. Boxes made from higher-grade paper and multiple layers typically exhibit increased strength. Furthermore, the thickness of the cardboard, measured in points, helps gauge its resistance to punctures and tears. Another important consideration is the box's construction method; for instance, boxes with reinforced corners and seams are more robust and suitable for shipping fragile items. Properly assessing these factors will enable you to choose a corrugated box that meets your specific shipping requirements effectively.

When it comes to shipping, selecting the right size corrugated box is crucial for protecting your items and reducing shipping costs. A perfect fit not only minimizes movement during transit but also prevents potential damage. Measure your items carefully, accounting for any additional packing materials like bubble wrap or foam peanuts that you might use. This will help you determine the dimensions of the box needed to hold your items securely.

Tips: Always aim for a snug fit, but avoid packing your items so tightly that they risk being crushed. Remember to consider the weight of the items as well; heavier objects may require stronger, double-wall boxes for added protection. Additionally, it's wise to leave some space for cushioning to safeguard against shocks and drops during delivery.

Consider using a box calculator tool, which can simplify the process of finding the right size box. By inputting your item dimensions, you can quickly find the most suitable box option without any guesswork. Additionally, explore options for box customization to ensure you get the perfect size for unique-shaped items. This not only enhances safety during shipping but can also improve the overall customer experience.

When selecting the best corrugated box for shipping, understanding industry standards is essential to ensure safety and efficiency. The most commonly used standard for corrugated boxes is the American National Standards Institute (ANSI) Z50.1, which provides guidelines on the construction and performance of corrugated fiberboard. These standards help determine factors such as box strength, weight capacity, and stacking ability. Familiarity with these guidelines helps businesses choose boxes that can withstand the rigors of transportation while protecting their contents from damage.

Additionally, the International Safe Transit Association (ISTA) offers testing procedures to evaluate the performance of packaging under various shipping conditions. Compliance with ISTA standards not only demonstrates a commitment to quality but also minimizes the risk of product loss or damage. By aligning packaging choices with these industry standards, shippers can enhance their credibility and ensure their products reach customers in excellent condition. This careful consideration of corrugated box specifications can ultimately lead to improved customer satisfaction and reduced shipping costs.

When selecting the right corrugated box for shipping, cost analysis plays a pivotal role in achieving a balance between quality and price. Understanding the different pricing structures associated with corrugated materials can facilitate an informed decision that maximizes shipping efficiency. For instance, opting for high-quality, durable boxes may involve a higher upfront cost, but the investment often pays off by reducing damages during transit and minimizing return rates. Analyzing the long-term benefits versus initial spending is essential for businesses looking to streamline their shipping operations.

Moreover, it is important to consider the specific needs of the products being shipped. Lightweight items may thrive in a more economical box, while heavier or fragile products necessitate robust packaging to ensure safety and reliability. By evaluating the weight, size, and fragility of your shipments, it becomes easier to determine the most cost-effective solution. Additionally, exploring bulk purchasing options can yield further savings, allowing businesses to procure quality boxes at reduced rates. Balancing these factors will not only help maintain budgetary constraints but also contribute to a more efficient shipping cycle.

Get Free Estimate!